+GF+ MIKRON MIKRON VCP 1000 Duro

+GF+ MIKRON MIKRON VCP 1000 Duro

orCall +1 262-320-3399

Description

VERTICAL MACHINING CENTERS

MIKRON VCP 1000 Duro

SUBJECT TO AVAILABILITY, AND TERMS AND CONDITIONS

FOLLOWING, WE OFFER FOR YOUR CONSIDERATION:

One used 2003 MIKRON GFMS-VCP 1000 Duro 3-Axis Vertical Machining Center:

Machine made in Nidau, Switzerland

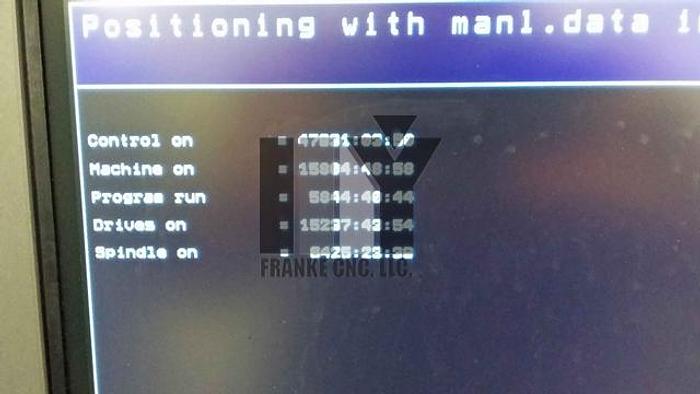

HEIDENHAIN iTNC530 Control with electronic handwheel & Ethernet interface

The VCP range was specifically designed to meet the highly demanding

requirements of the mould and die industry as well as the production of

parts requiring high accuracy.

The following features are designed specifically for the high accuracy

requirements of mould making:

-MASSIVE 21,716 lbs polymer concrete (man made granite) base. This

composite offers excellent vibration dampening characteristics:

approximately 10 times greater than cast iron and significantly better

than welded construction. A high degree of dampening is essential when

working with high feed rates, high acceleration, and is required for

superior surface finishes. The structure of the VCP 1000 Duro makes it

ideal for difficult applications, such as hard metal machining, where any

transmitted vibration leads to increased wear or fracturing of the cutter.

-SWISS made Step-Tec motor spindle with active external spindle chiller

-Direct measurement all axes via HEIDENHAIN linear glass scales

-High precision, widely spaced linear guides in all three axes, 6 roller

bearing skates each in X and Y-axes, as well as 4 in the Z-axis give the

best rigidity and robustness

-Large diameter high precision recirculating ballscrews are used to

transmit the drive forces to the axes

-HSK 63 spindle taper for maximum rigidity, tool life, and best surface

quality finish

-WORK AREA-

-HIGH PERFORMANCE MOTOR SPINDLE-

-FEED DRIVES-

-TOOL CHANGER-

-SAFETY EQUIPMENT-

-WORK TABLE-

-EQUIPPED WITH-

BLUM Laser Tool Measuring of tool length & diameter, also with broken tool

detection

RENISHAW MP12 infrared parts measuring probe

Completely enclosed work cabin

Chip conveyor

Side window for loading in extra large parts

Ethernet interface on control

Active external spindle chiller

PRICE QUOTED IN UNITED STATES DOLLARS

Specifications

| Manufacturer | +GF+ MIKRON |

| Model | MIKRON VCP 1000 Duro |

| Year | 2003 |

| Condition | Used |

| Stock Number | 064196 |

| Status | Available |

| Number of axis | 3-Axis |

| Tool changer | 30 ATC |

| Control | TNC 530 |

| Spindle | 20,000 rpm |

| Spindle taper | HSK 63 |

| X axis | 39.4" (1,000 mm) |

| Y axis | 25.6" (650 mm) |

| Z axis | 19.7" (500 mm) |

| Traverse path x (longitudinal) | 39.4" (1,000 mm) |

| Traverse path y (lateral) | 25.6" (650 mm) |

| Traverse path z (vertical) | 19.7" (500 mm) |

| Ac-motor spindle drive power 40% dc | 21.4 HP (15/16 kW) |

| Spindle speed | 12-20,000 rpm |

| Rapid traverse linear axes x/y/z | 1,181 ipm (30 m/min) |

| Feed force x and y/z | 7,000/9,000 N |

| Storage pockets | 30 positions |

| Maximum tool diameter | 3.5" (90 mm) |

| Maximum tool length | 11.8" (300 mm) |

| Maximum tool weight | 17.6 lbs (8 kg) |

| Tool change time | Approximately 9 seconds |

| Chip to chip times | Approximately 12 seconds |

| Door opening to the front | 40.9" (1,040 mm) |

| Window opening to the side | 33.3" x 38.5" (845 mm x 977 mm) |

| Table surfaces area | 51.2" x 23.6" (1,300 mm x 600 mm) |

| Maximum table load | 3,527 lbs. (1,600 kg) |

| Clamping slots | 14-H12 (H7) |

| Distance slot to slot | 2.6" (65 mm) |